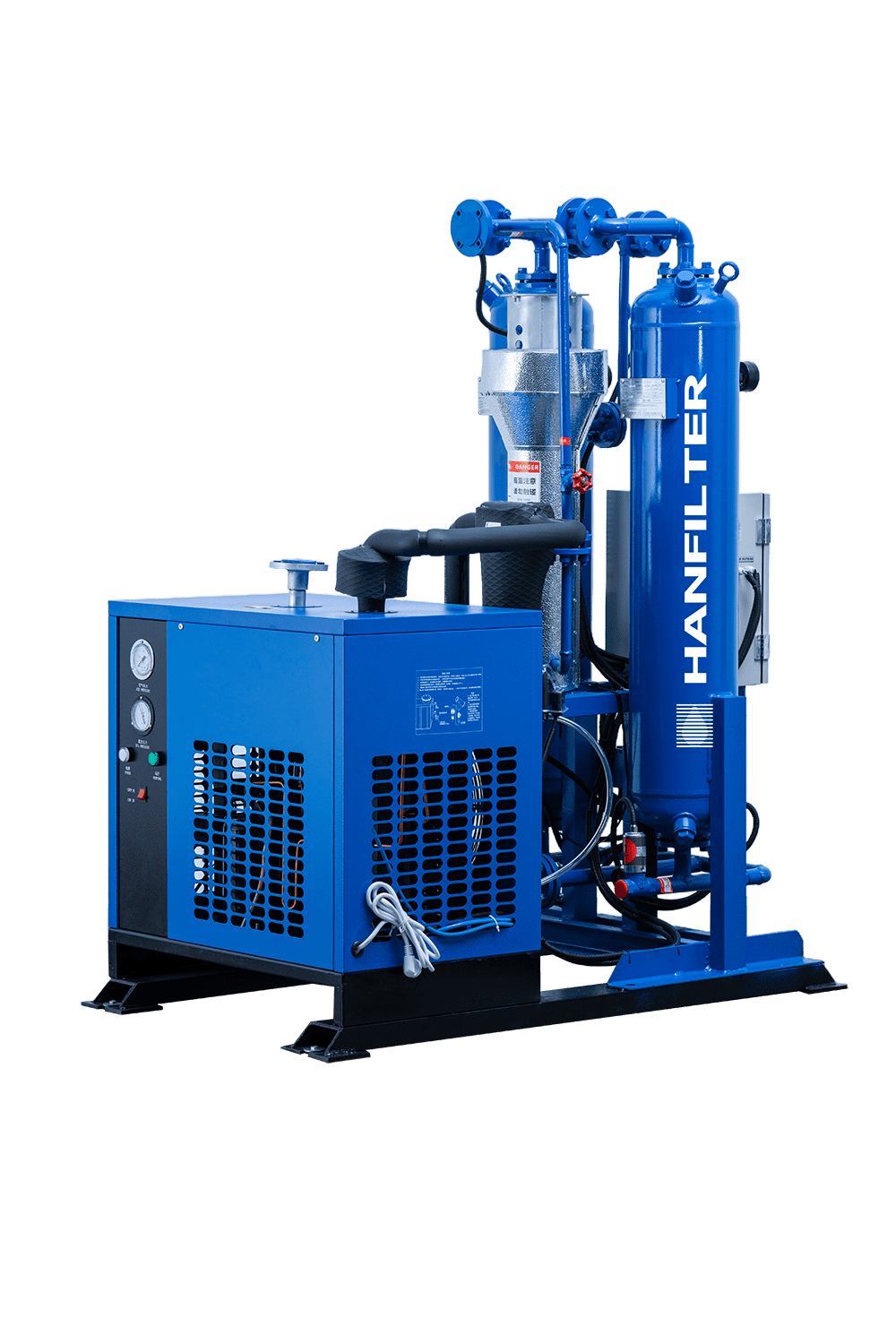

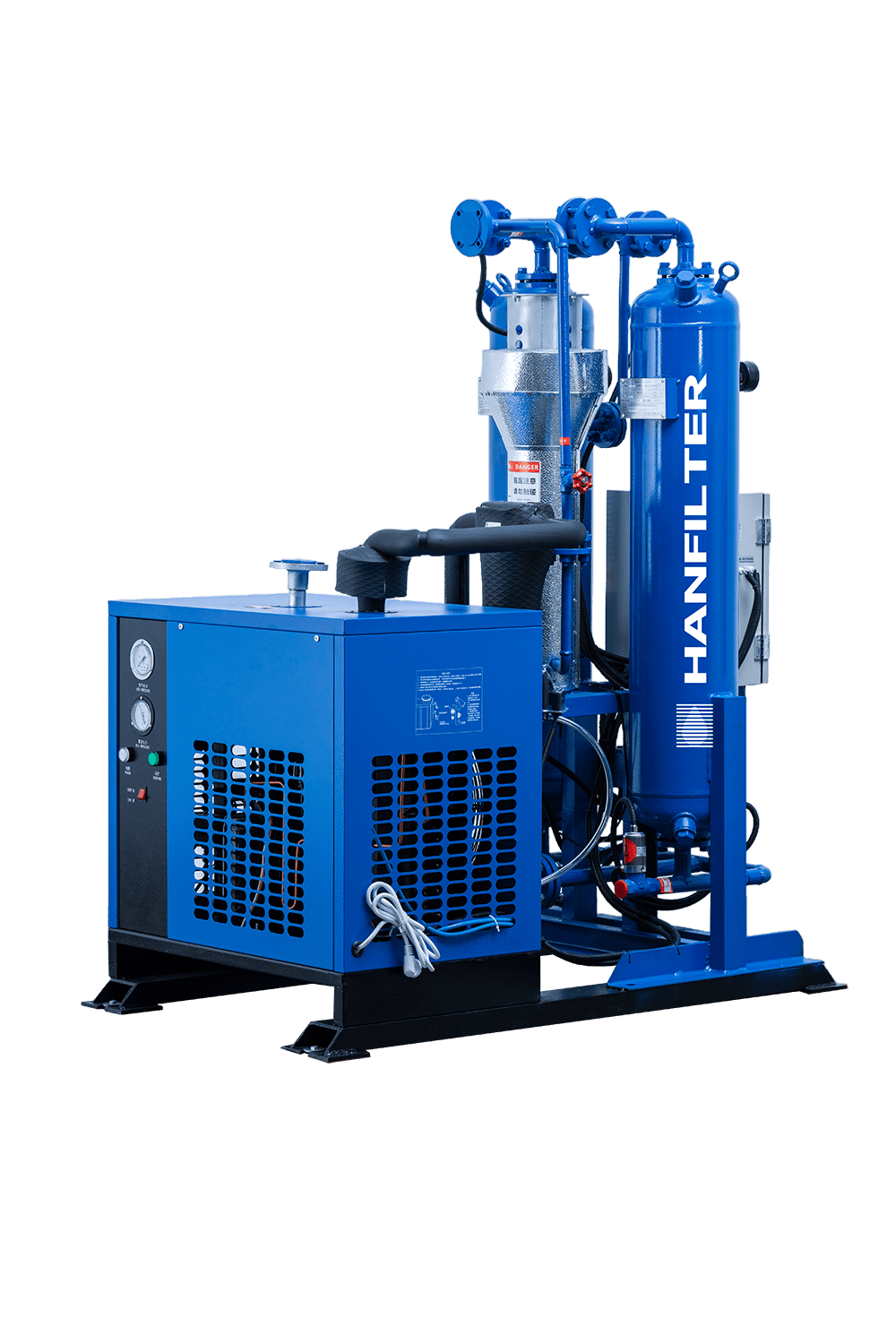

1. This machine employs a two-stage drying system for comprehensive drying. It utilizes a refrigeration drying system as the primary stage for pre-drying, followed by an adsorption drying system as the secondary stage for precision drying. Through a well-designed thermal combination, the system achieves the goal of deep drying.

2. The refrigeration drying system operates based on the variation of water vapor content in the air with pressure and temperature. When compressed air is cooled close to freezing point (0℃) through a refrigeration system, the oversaturated water vapor in the air condenses into liquid water droplets. By mechanically separating the water, the system effectively eliminates moisture, accomplishing the pre-drying objective.

3. The adsorption drying system utilizes special porous surface solid adsorbents such as activated alumina and molecular sieves. Based on the principles of molecular surface adsorption kinetics and variable-temperature adsorption, this system operates by adsorbing water molecules from the air onto the surface of the adsorbent at room temperature. During regeneration at high temperatures, the adsorbed water molecules are desorbed from the adsorbent's surface. Partially dried air is then used to blow and remove the desorbed water molecules, achieving the goal of deep drying.

Applicable industries:

Typically used in industries that require the cooling and removal of moisture from compressed air. These include manufacturing, food and beverage, pharmaceuticals, textiles, chemicals, and the power industry.

Delivery time:3 weeks ~ 6 weeks.