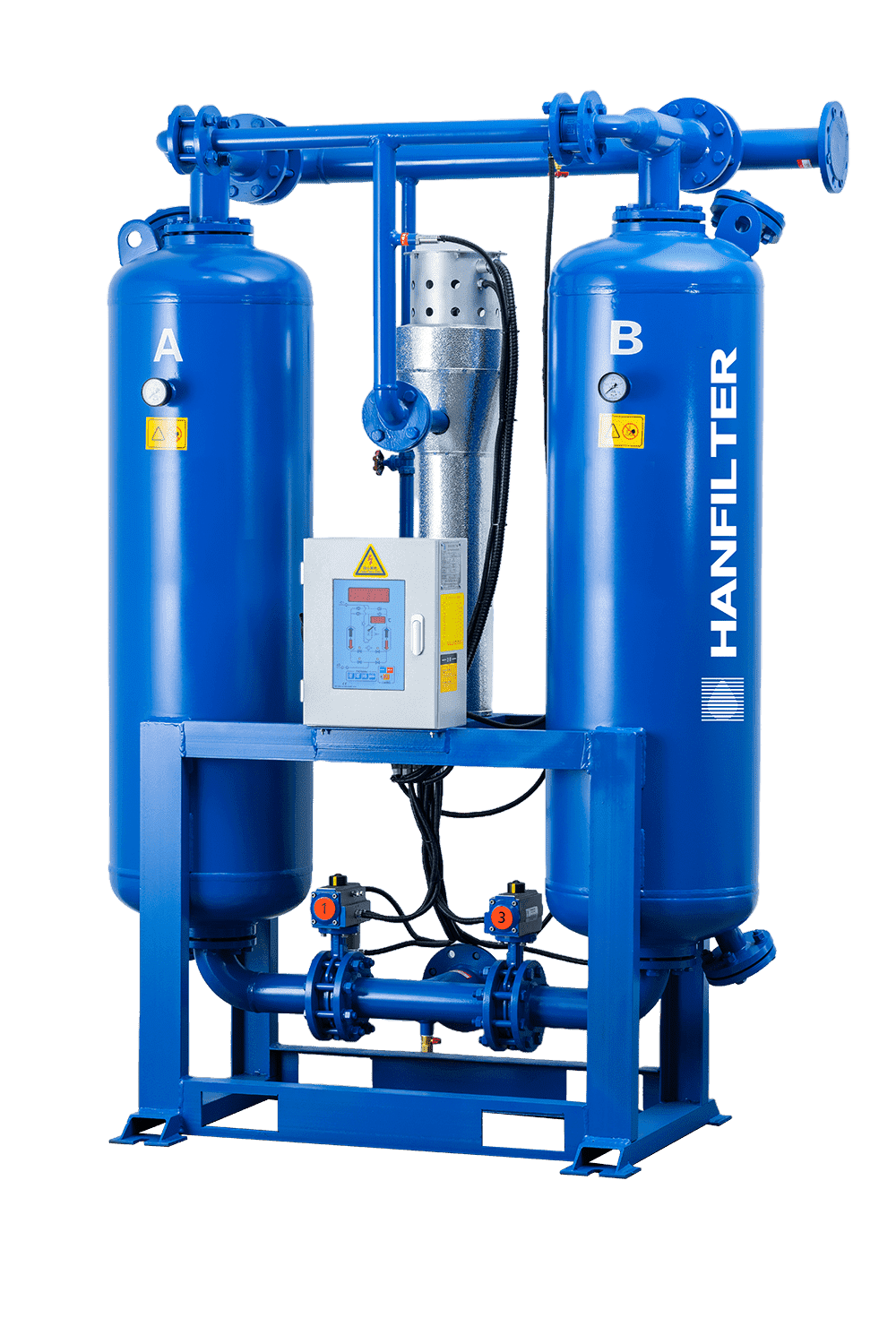

The Micro Heat Regeneration Adsorption Compressed Air Dryer is a purification device that utilizes molecular forces on the surface of porous solid substances to extract moisture from gases, achieving lower dew point temperatures and providing clean, dry air. It uses activated alumina as the adsorbent, with pore sizes similar to water molecules, and employs the internationally advanced principles of variable-temperature and variable-pressure adsorption. During adsorption at room temperature, the vapor pressure of water molecules in the air exceeds that in the adsorbent, causing water molecules to enter the adsorbent, condense into water droplets on its surface, and release condensation heat, storing this heat in the upper part of the adsorption tower.

During regeneration, approximately 5% of dry air is heated to around 120°C to 150°C through a heater and passes through the regeneration cylinder, allowing water molecules in the adsorbent to escape. Simultaneously, the heat stored in the adsorption tower aids in saving the power of the heater. The adsorbent undergoes a cycle of adsorption, regeneration, and re-adsorption, providing continuous adsorption drying of compressed air to achieve deep drying. The main technical indicators of this product have reached the level of similar models abroad, making it the preferred equipment for users seeking a pressure dew point below -20°C.

The dual-tower system operates alternately, continuously delivering dry and clean compressed air. The purified air achieves a low-pressure dew point, ensuring deep drying to provide water-free, oil-free, high-purity compressed air, meeting various gas requirements. Due to the use of a heater to heat atmospheric air, the regeneration effect is excellent, and energy consumption is minimal.

Applicable industries:

Typically used in industries that require the cooling and removal of moisture from compressed air. These include manufacturing, food and beverage, pharmaceuticals, textiles, chemicals, and the power industry.

Delivery time:3 weeks ~ 6 weeks.